Restaurants operating in a sector where ‘quick’ is a defining characteristic, obviously face more urgent time-pressures than, say, your typical fine dining establishment. Of course, even up-scale eateries aren’t immune to impatient customers.

But the modus-operandi of a QSR enterprise is entirely dependent on a swift service from kitchen to customer, be it at point of sale or the front-door. The main snag here is that the actual food needs to palatable as well. For the sake of long-term success, it’s important to balance speed with quality. So how to restaurants approach each requirement?

.jpg?width=636&height=424&name=18.03_incontent1(1).jpg)

How Do Fast Food Restaurants Produce Food Quickly?

The traditional QSR model is specifically designed for swift production. The larger fast food chains in particular, rely on the kind of assembly-line efficiency that necessitates structured, linear workflows and station-specific roles. To keep up with demand, each station, whether grilling, frying, assembling, or packaging, has to function in perfect unison.

How Do Fast Food Restaurants Ensure Quality?

Ensuring food quality requires standardised food prep processes and strict guidelines regarding batch cooking and order holding times. Quality control checks are also put in place at both production and procurement levels.

In a pre-digital age, both of the above systems worked well. But today, these operational models are being stress-tested to the limit due to rising customer expectations and shifting consumer habits. Inconsistencies and deterioration in food presentation are now increasingly common. For QSRs, a change of approach is now essential. It’s the only way to balance production speed and quality.

.jpg?width=636&height=424&name=18.03_incontent2(1).jpg)

The Uber Generation

The fast food consumer base is dominated by Gen Z and Millennials. Far less inclined to wait around, they also expect their food to be of a high quality, their ordering experiences effortless and convenient - for QSRs especially, much of this convenience is facilitated by mobile ordering.

Traditionally, QSRs could focus primarily on in-house, drive-through and takeaway orders (a challenge in itself). But now orders also originate from websites and third-party delivery apps. The sudden and unpredictable demand surges that typically arise, force fast food kitchens to accelerate production, often at the expense of quality.

How then, do QSRs satisfy a more demanding and expectant consumer base while ensuring their food is of a high standard? Essentially, it’s about adopting the kind of technology that enhances existing operational structures. What follows are some of the most critical areas in which tech can help to balance speed and quality.

Tech-Driven Order Management

Perhaps more than any other food service, QSRs depends on streamlined ordering processing at front-of-house. And the vast majority of current tech solutions accommodate this requirement by featuring intuitive POS systems that allow for fast, error-free ordering.

Unfortunately though, not all systems integrate orders made via third party delivery apps such as Deliveroo or Uber Eats. This means that order-takers have to rely on proprietary third party tablets leading to confusion and ultimately a slower service.

The impact is also felt in terms of restaurant kitchen management. Without smart order routing, high priority orders can get lost in the production queue. Sequencing becomes a problem as well – some orders are prepared too early, some too late.

This kind of mismanagement leads to overcooked and cold food, not to mention excessive waste. To solve the problem, the more sophisticated restaurant management systems now include order injection. So what is food order injection in restaurants?

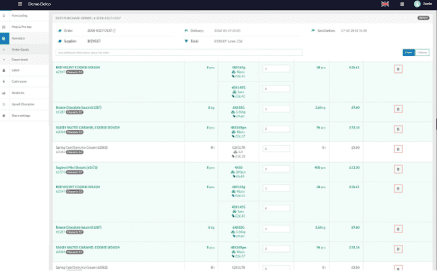

Order Injection

Simply put, order injection is a fully automated process in which all orders from all channels, be they in-house or external, are routed into a single kitchen workflow. Crucially, no manual input is required for orders made via a third party app or website. Instead, they’re sent directly to a kitchen display system which then presents each order to staff along with critical information about timing and prep. This kind of smarter order tracking with a KDS can be of immense help with regards speed and efficiency.

Order Sequencing

From the KDS, kitchen staff can see the orders as they come in, together with cooking times and completion deadlines. If too much time has elapsed on an order, the item is flagged for urgent attention. For external orders, additional information is usually included such as where and when an item should be delivered and when it should be ready for collection.

To help this process further, next-gen platforms can also shift priorities in order to optimise production. For a busy fast food kitchen, this kind of automation can ensure faster service, ensuring that the food isn’t stone cold on arrival.

But even with a sophisticated order management system in place, the demand surges brought about by delivery app exposure can still lead to bottlenecks and delays. It’s a problem that’s further confounded by the flash promotions and time-limited deals often run by the likes of Uber Eats and Deliveroo. This is why accurate forecasting is so important.

Tech-Driven Forecasting

Without accurate forecasting any F&B operator will struggle to recognise and anticipate demand fluctuations. While many of the larger QSR chains use qualitative and quantitative techniques, for smaller establishments, forecasting is often an inexact, time-consuming process requiring spreadsheet and paper-based analysis. This is however changing.

AI-Driven Forecasting

Sales forecasting for restaurants has undergone something of a revolution in recent years. Tapping into the formidable potential of artificial intelligence and machine learning, the latest ePOS systems are able to produce restaurant forecasts with up to 98% accuracy. But how does restaurant AI forecasting work?

Restaurant AI forecasting is only effective with a fully integrated platform that seamlessly connects POS terminals, inventory, and kitchen operations. With the use of advanced algorithms, it analyses historical sales metrics for trends and variations. At the same time, the system factors in real-time data and external influences such as the weather and local events.

In contrast to traditional forecasting methods which follow fixed patterns, machine learning models are also able to find non-obvious correlations such as the impact of say, delivery app promotions or weather-induced demand spikes.

Staff and Inventory Alignment

From this data, the system helps the QSR operator to prepare for the inevitable fluctuations that will occur. With such precise forecasts, it becomes much easier for managers to align kitchen staffing levels with demand. Inventory balancing is also improved putting an end to stock outs and ‘just in case’ purchases for demand spikes that never happen.

Food Prep and Batch Plans

Next-gen restaurant management systems also use their forecasting data to automatically generate preparation and batch plans, while at the same time adjusting production schedules for timely completion.

Sporadic prep is therefore eliminated, ensuring that food doesn’t deteriorate due to excessive holding times. And given that prep plans tend to include specific production steps, staff are able to keep production moving without oversight.

Tech-Driven Driver Management

With QSR consumer habits as they now are, restaurant driver and delivery management is vital for ensuring service speed and food quality. But it’s a process that’s become a little more complicated since the rise of third party aggregators.

For many operators, driver control has been outsourced. Food handling training is the responsibility of the delivery company. And the drivers serve multiple restaurants so they often have to pick up orders from other establishments. To further confuse the situation, QSRs often operate in-house delivery services as well.

Chaos then ensues. Orders often sit too long before pickup so the food goes cold, deliveries arrive late due to stacked consignments, and poor handling results in damaged items. Really, the only viable solution for quick service eateries is to rely on technology to gain control of such a convoluted process. With this in mind, how do fast food restaurants manage third party drivers?

Many restaurants use proprietary tablet-based apps provided by third party aggregators. While these apps are powerful and easy to use, management becomes problematic if a restaurant partners with multiple delivery services. Juggling multiple tablets leads to fragmented workflows, confusion and inefficiency. The solution is to utilise a unified restaurant management system.

Unified Driver Management Technology

More and more operators rely on advanced restaurant management systems that fully integrate with third party services and which allow them to manage drivers via a single dashboard. These provide managers with a complete oversight of their entire delivery operation on both a fleet and drive-specific level. Both-way communication between driver and operator tends to be instant while the drive themselves are often furnished with their own app to further improve efficiency.

AI and GPS Streamlining

Again, the latest technologies can play a crucial role, here. AI assigns drivers based on location, availability and route efficiency, order batching is optimised to prevent the delays caused by stacked ordering. In addition, map-based GPS interfaces allow managers to track driver locations precisely and in real time.

Final Thoughts

Balancing fast food production with quality and consistency is no doubt a challenge. In such a competitive and volatile industry, QSRs really have no recourse but to adopt the latest technologies. It’s the only way to satisfy customers and ensure business longevity.

Learn how Syrve can help your fast food restaurant in each of the areas mentioned above